PATENT

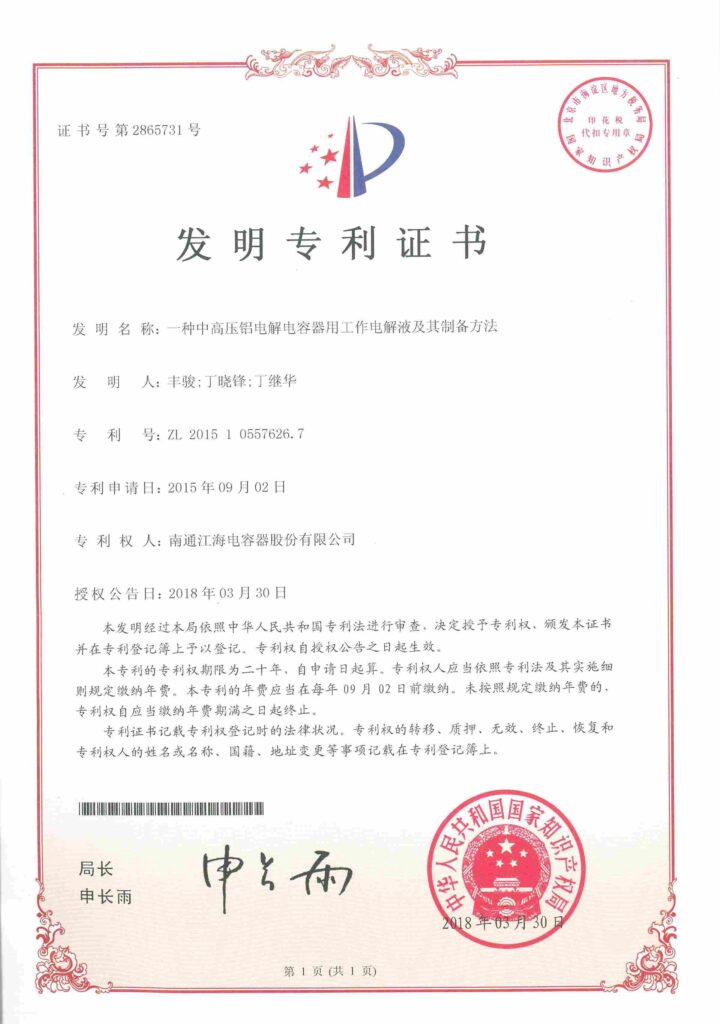

The invention relates to a working electrolyte for medium and high voltage aluminum electrolytic capacitor and a preparation method thereof, which comprises: 70% ~ 90% solvent, 9% ~ 29% solute, 0.1 ~ 1% hydration inhibitor and 0.1 ~ 1% hydrogen absorbent by weight percentage. The preparation method includes: (1) heating the solvent to 60-90 ℃ by weight percentage, adding solute, stirring and heating to 85-95 ℃ for complete dissolution; (2) adding the solution of step (1) to hydration inhibitor, heating to 95-145 ℃; then cooling to 85-95 ℃, adding hydrogen absorbent to obtain electrolyte. The invention overcomes the shortcomings of the electrolytic capacitor that the electric capacity drops greatly under the high temperature load and the leakage current increases after the high temperature and no load, so that the technical parameter index of the capacitor remains stable after the long-term high temperature; the preparation method has simple process, low cost and good application prospect.

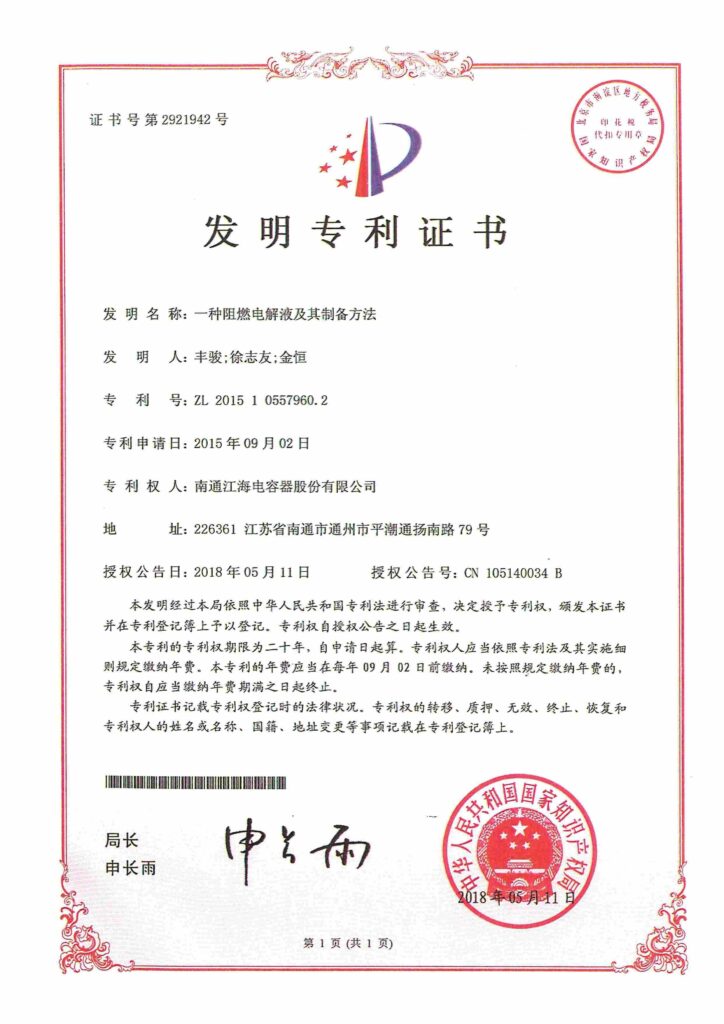

The invention relates to a flame-retardant electrolyte and a preparation method thereof, which comprises: according to the weight percentage, glycol 63% – 86.5%, silica 1% – 3%, boric acid 5% – 15%, ammonium pentaborate 5% – 10%, mannitol 1% – 5%, o-nitroanisole 0.5-2.0% and phosphoric acid 1-2%. The preparation method includes: (1) heating glycol to 60-75 ℃, adding boric acid, ammonium pentaborate and mannitol successively, heating to 95-105 ℃, stirring until it is completely dissolved; (2) adding silica into the solution, stirring until it is completely clarified; (3) cooling the solution to 65-70 ℃, adding o-nitroanisole and phosphoric acid, naturally cooling to obtain electrolyte. The electrolyte of the invention is not only resistant to high temperature and high pressure, but also can reduce the amount of hydrogen produced in the working process of the electrolytic capacitor, can reduce the vapor pressure of the electrolyte, and has flame retardancy.